|

Solution Components

|

A Sub-Function: Measure pedal movement |

A.1- Potentiometer

|

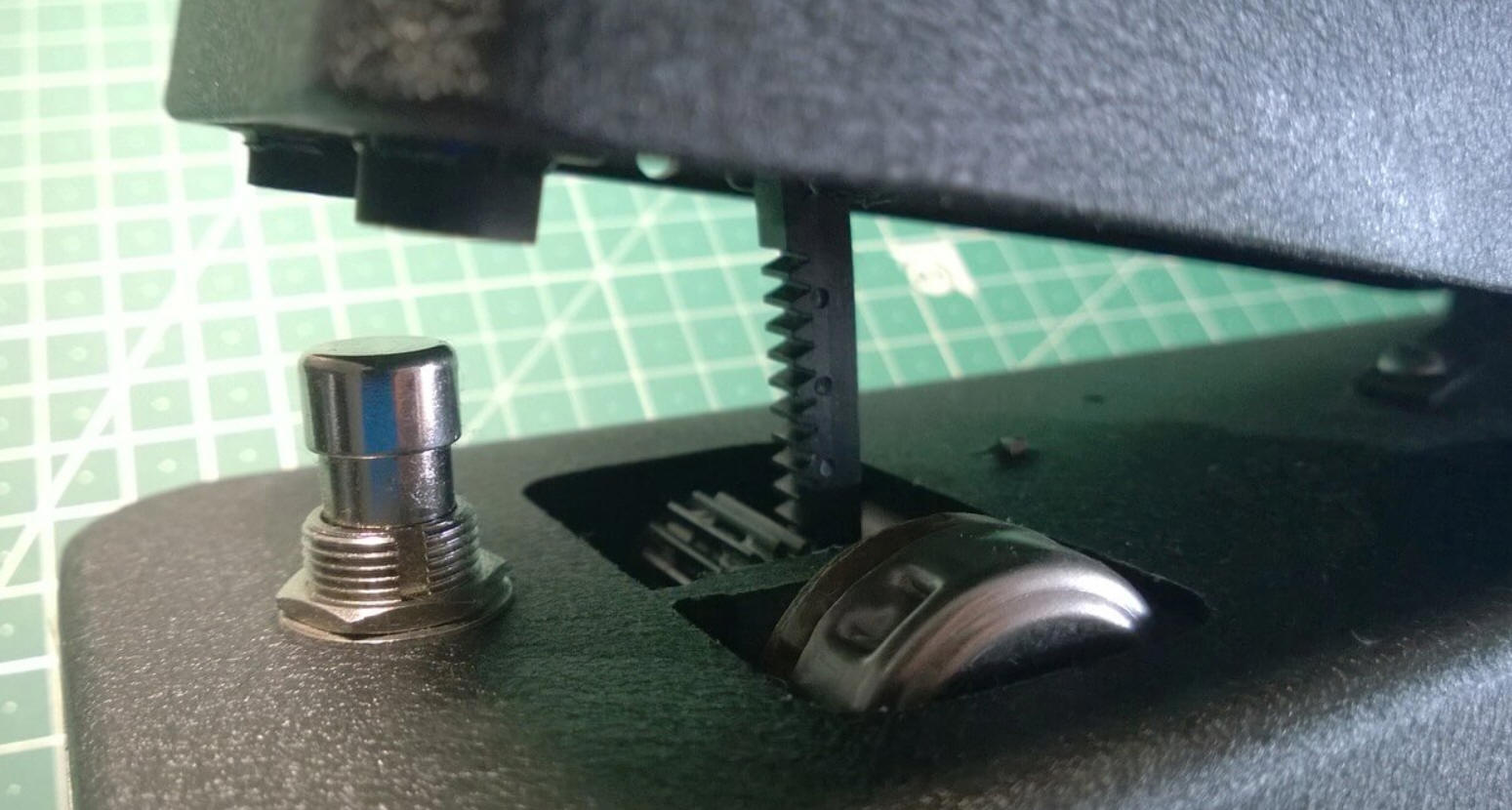

| Fig: Potentiometer setting via rack

in a wah pedal (source) |

|

Advantages |

Disadvantages |

| Cheap |

|

| Ready-made

variants available in pedal form |

|

| A Subfunction: Measurement

of pedal movement |

A.2 - Inductive displacement sensor

|

| Fig. Inductive displacement sensor(Source) |

|

Advantages: |

Disadvantages: |

| |

Expensive |

| |

Implement connection to pedal |

| A Subfunction: measure

pedal movement |

A.3 -Incremental encoder

|

Advantages: |

DIsadvantages: |

| Direction of

rotation could be used as an input variable by the user of

the pedal |

More expensive than potentiometers

|

| B Subfunction: Process

input data and derive actuator signal |

B.1 Microcontroller

|

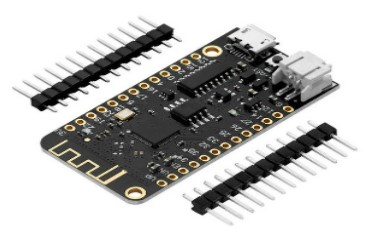

| Fig: Mikrocontroller ESP32

LOLIN

(Source) |

|

Advantages: |

Disadvantages: |

| Cheap |

|

|

More energy efficient |

|

| flexible

application possibilities |

|

|

B Subfunction: Process

input data and derive actuator signal |

B.1 Programmable logic controller

|

| Fig: Programmable logic controller |

|

Advantages: |

Disadvantages: |

| |

Program processing cyclically with

lower frequency |

| |

Expensive |

| C Partial function: reduce

free cord length |

C.1 Winding the line on a winch by means of a motor

|

Advantages: |

Disadvantages: |

| Conversion of

translational movement into rotational movement |

|

| Clean line

storage without knotting |

|

|

D

Subfunction: increase free cord length |

D.1 Mechanical freewheel

|

Advantages: |

Disadvantages: |

| low mass |

|

|

lowest possible moment of inertia during climb, as other

parts remain unmoved |

|

| D Subfunction: reduce free

cord length |

D.2 Turning of the drive unit (winch wheel to rotor of the

motor)

|

| Fig.: Stepper motor with coupling

on a shaft

(Source) |

|

Advantages: |

Disadvantages: |

| few components

needed |

Motor will apply counter-torque |

| Revolutions in

climb could be determined --> rope length could be

determined in the system |

|

| E Subfunction: Torque

transmission from drive to winch |

E.1 - mounting the winch on a shaft; The shaft is driven by a

bellows coupling

|

Advantages: |

Disadvantages: |

| Rigid

connection, no loss of kinetic energy through damping in

elastic components |

high accuracy requirements for the

assembly of the shafts (axial, radial & angular dimension) |

| E Subfunction: Torque

transmission from the drive to the winch |

E.2 - mounting the winch on a shaft; The shaft is driven by a

double loop clutch

|

Advantages: |

Disadvantages: |

|

anti-vibration |

Speed limitation (usually up to

3000 rpm) |

|

Inaccuracies when aligning the shafts do not endanger

concentricity |

|

|

| E Subfunction: Torque

transmission from the drive to the winch |

E.3 - Motor shaft to shaft connection with winch via belts

|

| Fig: Belt connection and with drive

(Source) |

|

Advantages: |

Disadvantages: |

| |

higher number of components:

transmission pinion, more roller bearings |

|

|

F

Subfunction: Motor variant |

F.1 - DC motor

|

Advantages: |

Disadvantages: |

| higher speeds

can be achieved |

|

| faster

response time compared to a stepper motor |

|

| F Subfunction: Motor

variant |

F.2 - Stepper motor

|

Advantages: |

Disadvantages: |

| no rotary

encoder necessary |

speeds limited |

| easily

controllable via microcontroller |

|

| F Subfunction: Motor

variant |

F.3 - Servomotor

|

Advantages: |

Disadvantages: |

| Accurate

positioning |

usually no continuous rotations |

| accurate

position feedback |

speeds limited |

| G Subfunction: line

guide for flight near the ground (takeoff and landing) |

G.1 - Elevation of the drone by landing gear

|

| Fig: Elevation of the drone by

landing gear(Source) |

|

Advantages: |

Disadvantages: |

| Increasing the

distance between the rotors and the line lying on the ground

--> less likely to get caught |

additional weight for the drones |

| low mass |

possibly slight negative impact on

flight duration |

| G

Subfunction: line guide for flight near the ground (takeoff

and landing) |

G.2 - Loading on elevated platform

|

Advantages: |

Disadvantages: |

| Erhöhung

Abstand zwischen Rotoren und auf Boden aufliegender Schnur

--> "Verfangen" unwahrscheinlicher |

Mobilität des Aufbaus deutlich

reduziert |

| G

Subfunction: line guide for flight near the ground (takeoff

and landing) |

G.3 -Line guide through eyelet near the bottom

|

| Fig: Eyelet(ring) that can be

brought close to the ground during takeoff and landing

(Source) |

|

Advantages: |

Disadvantages: |

|

Easy to use |

Eyelet must be

folded up during operation to avoid increased friction |

| Ensuring that

line is kept away from rotors at a favorable angle |

|

| H Sub-function:

energy supply of the system |

H.1 - a battery for the supply of the data processing unit and a

battery for the motor

|

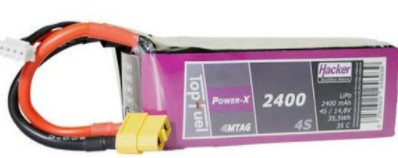

| Fig: Separate batteries for

microcontroller and motor |

|

Advantages: |

Disadvantages: |

| simple

interconnection |

costly |

| Batteries can

be replaced individually if there is a high energy

requirement |

|

| H Sub-function:

energy supply of the system |

H.2- One battery for the entire system with use of optocouplers

| Advantages: |

Disadvantages: |

| only one

battery required |

more

complex wiring |

| inexpensive |

|

| I Sub-function:

energy supply of the drone(on the drone) |

I.1 - Directly replace the original drone battery with the power

supply via a

cable

|

| Fig: Power supply with a

cable(without battery) |

|

Advantages: |

Disadvantages: |

| Allow light

weight system |

DJI Mavic 2 has an intelligent

battery which allow to start the drone. So we would need to

install and program a microcontroller to turn the drone on. |

| No flight time

limitation |

Complex system |

| I Sub-function:

energy supply of the drone(on the drone) |

I.2- STARTRC For DJI Mavic 2 Battery Extended Adapter to extract

an input power with Drone battery

|

| Fig: Power supply via STARTRC

adapter (with battery) |

| Advantages: |

Disadvantages: |

| Don´t need to

remove the original battery |

More weight |

| No flight time limitation |

|

|

J Sub-function:

Energy supply of the drone(on the ground) |

J.1 - Sliding electrical contact

|

| Fig: Sliding Contact BQLZR |

|

Advantages: |

Disadvantages: |

|

Transfer of energy |

wear of

sliding contacts |

| Rotating

connection |

|

|

J Sub-function:

Energy supply of the drone(on the ground) |

J.2- Inductive power supply

|

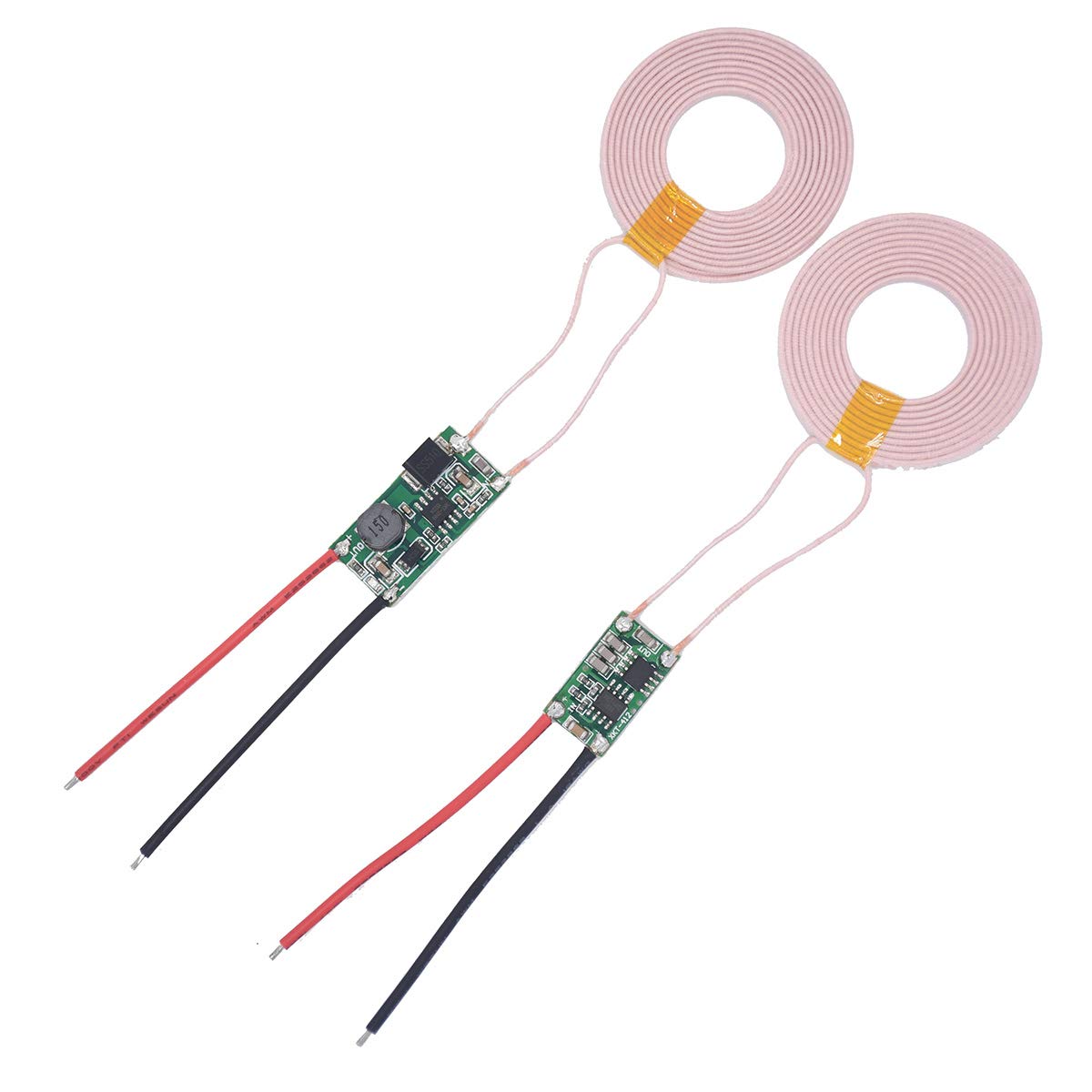

| Fig: Wireless power supplier |

| Advantages: |

Disadvantages: |

| Non-contact

transmitter reciever |

Large surface

for energy |

| |

loss of energy |

|