Requirements for the choice of force sensor are:

- size

- availability

- electrical connectivity

- need for signal

amplifier

Due to the size and shipping restraints, the round

FX1901 strain-gage sensor is picked. The plastic housing can be

removed to reduce the size of the unit. Force is applied on the

center bump. With a diameter of 19,2mm, it is suitable to be mounted

into the foot of a crutch.

Figure 3.8.1: Features of the FX1901 according to data shee

Figure 3.8.1: Features of the FX1901 according to data sheet

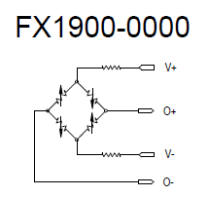

Figure 3.8.2: Strain-gauge layout of FX1901

Figure 3.8.2: Strain-gauge layout of FX1901 The sensor features 4 strain gages in

a configuration that is readable for the HX711 signal amplifier.

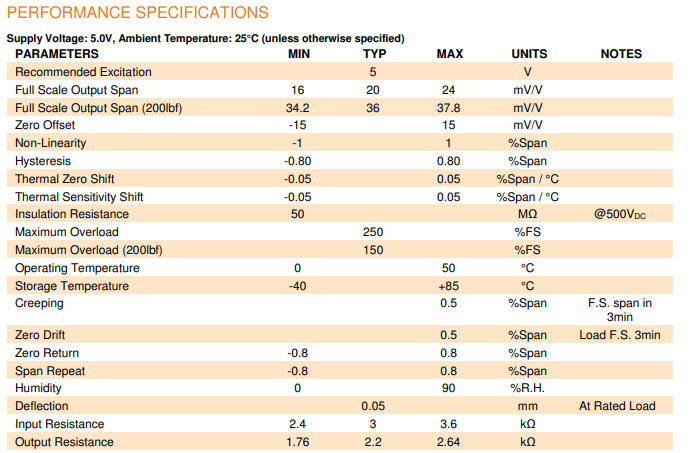

Figure 3.8.3: Technical specifications of the FX1901 sensor

Figure 3.8.3: Technical specifications of the FX1901 sensorThe main requirement characteristics for the choice of

microcontroller are:

- size

- wireless connectivity

-

low-power sleep modes

- power consumption when in use

- cost

Since the first demonstrator unit of the intelligent crutch is

to be built purely as a function demonstrator, the size and cost

requirements are secondary. Wireless connectivity is a must, also

low power consumption in standby and use should be demonstrated.

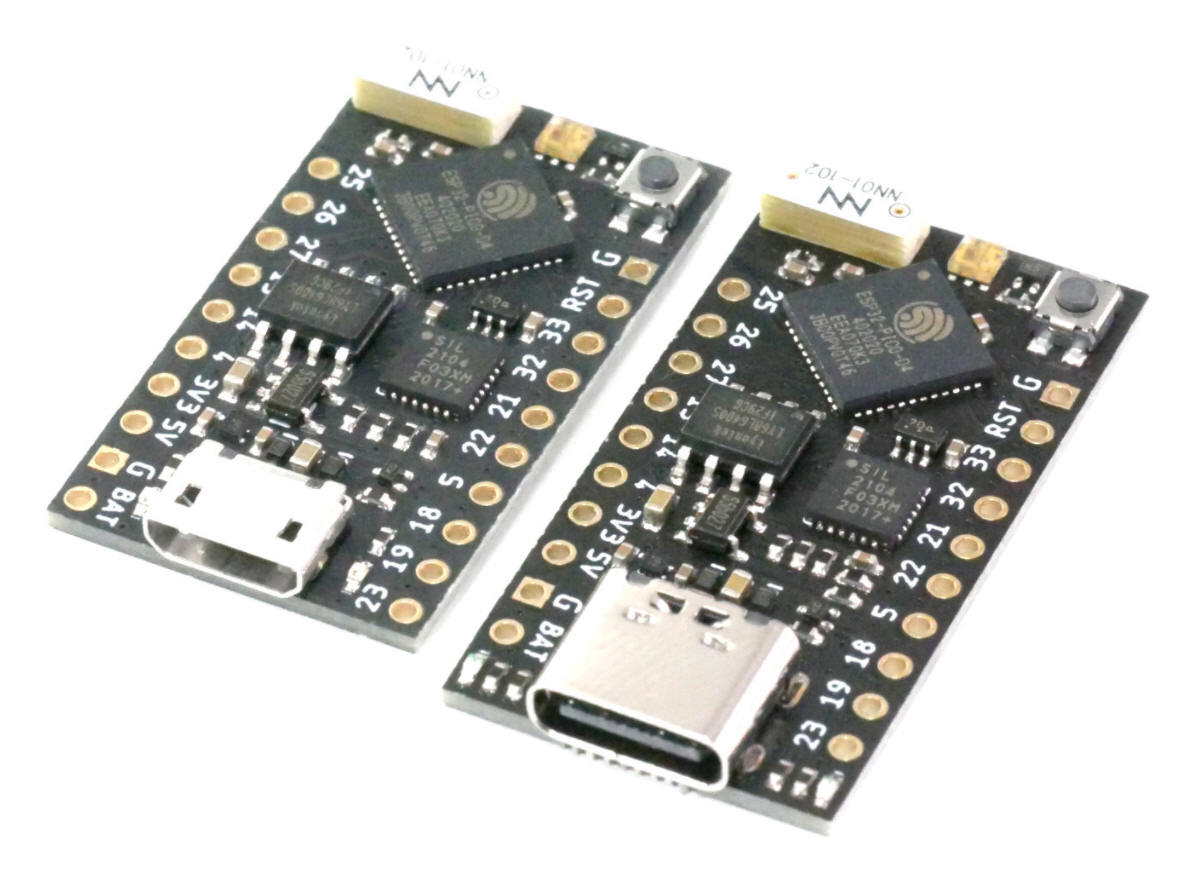

Figure 3.8.4: TinyPICO ESP32 boards with micro-USB (left) and USB-C (right)

Figure 3.8.4: TinyPICO ESP32 boards with micro-USB (left) and USB-C (right)

The TinyPICO is a ESP32 board which is very small (18mm x 32mm).

Compared to most regular ESP32 development boards, the number of

breakout-pins has been reduced. This will not affect the project,

since only a small number of sensors need to be connected.

The

TinyPICO offers a very low power consumption of

20uA when in deep sleep.

This suits the use case very well,

since it is possible to leave the device turned on for long periods

of time with no use.

The board is prepared to be powered directly

from a single-cell lithium battery. This suits the use-case of a

crutch very well, as the device must be very mobile.

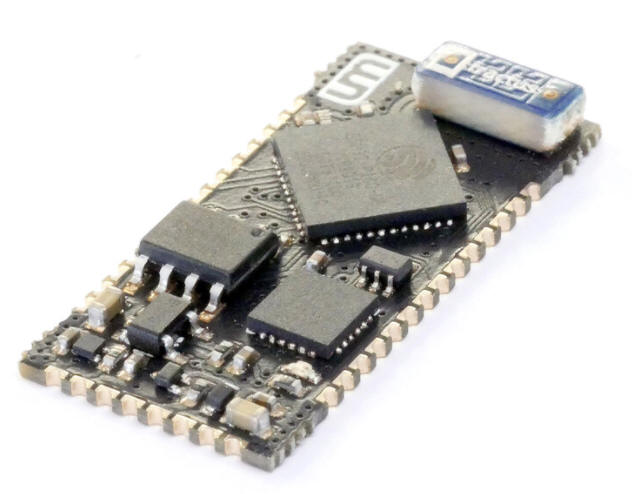

The TinyPICO Nano is a different variant of the same ESP32 board, which is SMD. The size is

therefore reduced to 13mm x 27mm.

Figure 3.8.6: TinyPICO Nano SMD board

Figure 3.8.6: TinyPICO Nano SMD board It is well suited for the integrated

PCB variant of the intelligent crutch. Manual soldering is possible.

The very small width make it theoretically possible to fit the

Microcontroller board into the tube of the crutch.