An iterative design process has been chosen to develop the whole

system. At the beginning, the first goal is to obtain raw weight and

accelerometer sensor data from two crutches as fast as possible.

This data will then be analized for feasability and to develop

algorithms to detect and accurately calculate the critical limb load

while walking:

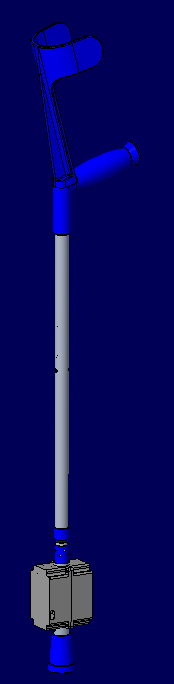

Figure 3.9.1: General concept of the intelligent crutch.

Figure 3.9.1: General concept of the intelligent crutch.

Develpment will take part in the following two parts:

1.

Test setup with reduced functionality:

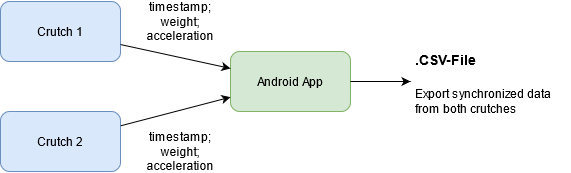

Equip two crutches simple and fast with microcontrollers, weight

sensors, accelerometers and batteries in form of breakout boards.

Synchronize measurements by pounding both crutches together and

searching for a peak in acceleration data. Send raw sensor data from

both crutches to android device. Show synchronized data from both

crutches and export it into one .csv-file for further analysis.

2. Fully functional

prototype:

Construct a

fully functional prototype with direct feedback for patient and GUI

for medical personnel. Design and fit PCB with electrical

components. Shrink down mechanical design accordingly.

To realize an efficient solution, a normal crutch will be

modified. The original upper part is unchanged. The lower inner tube

will be modified. It will still be possible to adjust the crutch

length in the usual way. The first step of mechanical development is mounting the weight

sensor. This must be done in a way that axial load is transfered

unchanged to the weight sensor while every lateral load is absorbed

by the crutch tube.

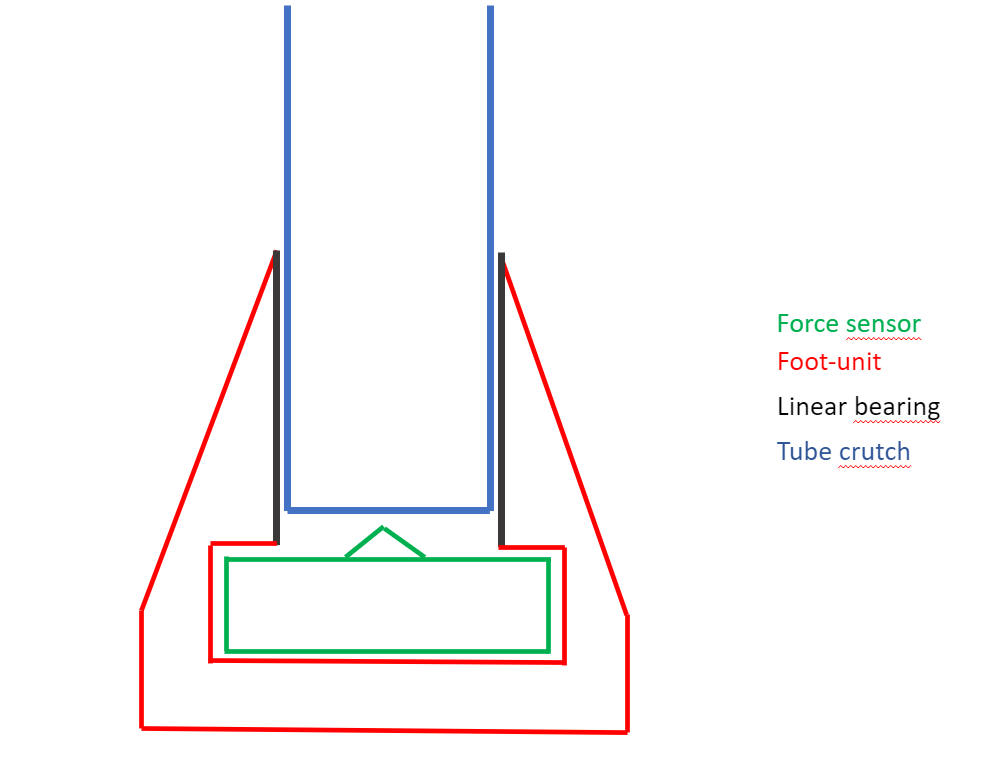

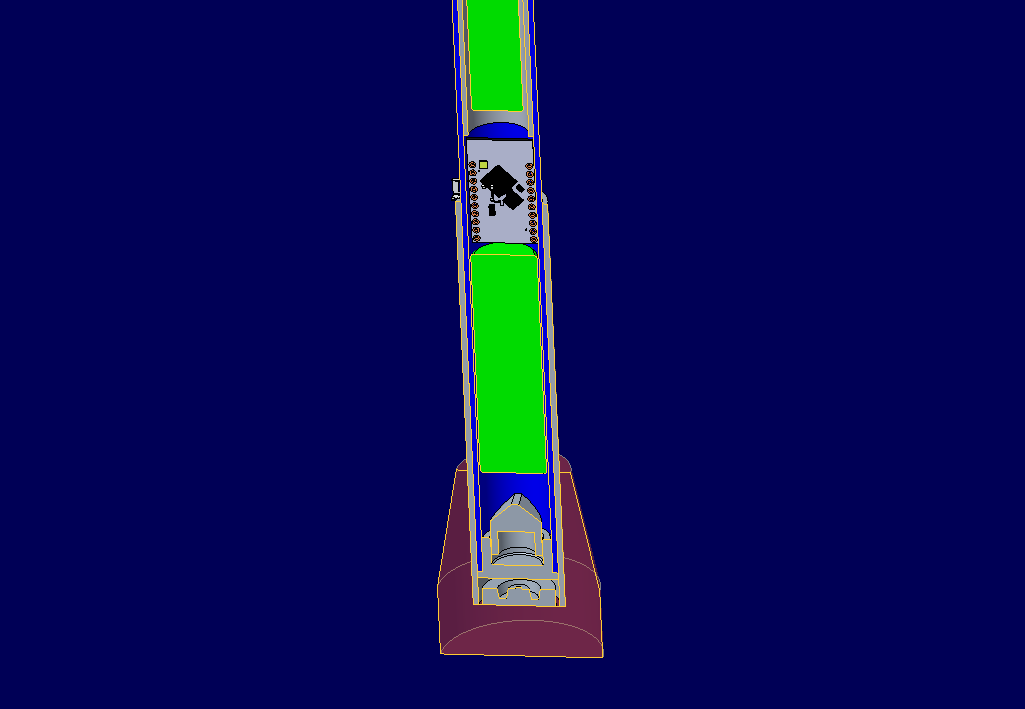

Figure 3.9.2: Design concept of the intelligent crutch.

Figure 3.9.2: Design concept of the intelligent crutch.A first sketch of a possible mounting position of the FX1901

force sensor. The crutch tube is closed at the bottom, so it can

deliver force into the center bump of the force sensor. The main

foot-unit can be 3D-printed in TPU, a high-strength, slightly

flexible material.

Depicted in black is a linear bearing,

possibly an aluminium tube. It takes the side forces, which are

created by the torque of setting the crutch foot on its edge, which

happens in use. It still allows linear movement without significant

friction, so the force sensor can get accurate readings. In the

final design, the opening on top must allow the assembly of the

sensor into the main foot unit.

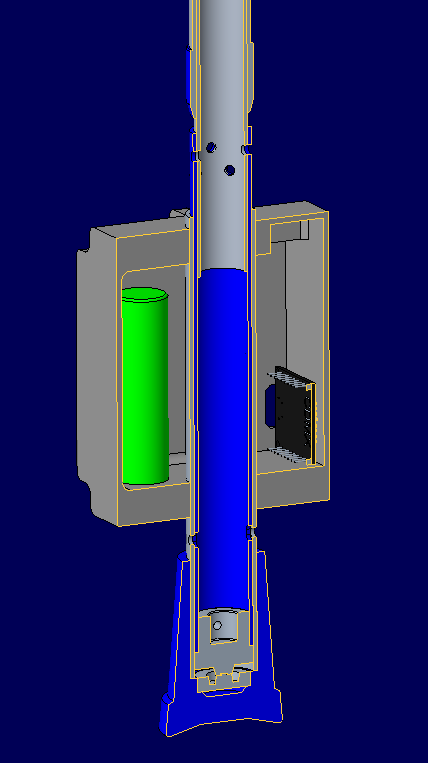

The following pictures show

CAD design for the test setup. Alle electric components are housed

inside a 3D-printed box.

Figure 3.9.3: Mechanical Design of the intelligent crutch.

Figure 3.9.3: Mechanical Design of the intelligent crutch.

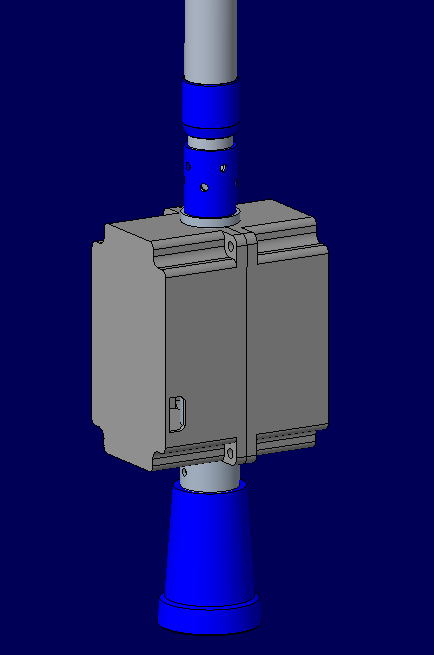

Electrical components will be integrated inside crutch

tubing for the final prototype:

Figure 3.9.4: Electrical components integration

Figure 3.9.4: Electrical components integration